低温真空刮板蒸馏设备 Low-Temperature Vacuum Scraped

日期:2024-06-15 / 人气: / 来源:沁聚环保

低温真空刮板蒸馏设备

Low-Temperature Vacuum Scraped Film Distillation Equipment

Low-Temperature Vacuum Scraped Film Distillation Equipment

一、 设备介绍:

主要在真空负压作用下降低原液的沸点,使原液在较低温度下(约30多度)沸腾蒸发,通过冷凝系统将蒸汽冷凝成液态水,并排出系统。浓缩减量出水率可达95%。该设备减少了企业废液处理成本,占地小,移动便捷,自动化程度高,只需电能和少量压缩空气。

Equipment Introduction: The main function is to lower the boiling point of the original liquid under vacuum pressure, causing it to boil and evaporate at a lower temperature (approximately 30 degrees Celsius). The evaporated steam is condensed into liquid water by the condensation system and then discharged from the system. The concentration reduction rate can reach up to 95%. This equipment significantly reduces the waste liquid treatment costs for enterprises, with advantages such as a small footprint, mobility, high automation level, and requiring only electrical energy and a small amount of compressed air.

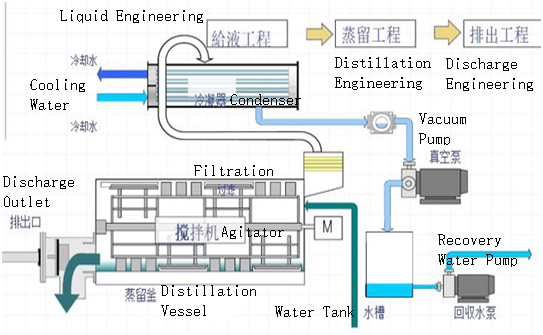

二、 处理流程:

不同类型废液需采取不同处理措施,如含油类原液需前端搭配油水分离机,后端搭配膜过滤以提高蒸馏水水质;含有机物或粘性液体需絮凝后蒸发以减少运维成本;含盐类低浓度液体可直接蒸发,高盐液体建议使用低温刮板结晶设备。

Treatment Process: Different types of waste liquids require different treatment measures. For example, oil-containing raw liquids require an oil-water separator at the front end and membrane filtration at the back end to improve the quality of distilled water. Organic or viscous liquids need flocculation before evaporation to reduce maintenance costs, while low-concentration liquids containing salts can be directly evaporated. For high-salt liquids, it is recommended to use low-temperature scraped crystallization equipment.

主要在真空负压作用下降低原液的沸点,使原液在较低温度下(约30多度)沸腾蒸发,通过冷凝系统将蒸汽冷凝成液态水,并排出系统。浓缩减量出水率可达95%。该设备减少了企业废液处理成本,占地小,移动便捷,自动化程度高,只需电能和少量压缩空气。

Equipment Introduction: The main function is to lower the boiling point of the original liquid under vacuum pressure, causing it to boil and evaporate at a lower temperature (approximately 30 degrees Celsius). The evaporated steam is condensed into liquid water by the condensation system and then discharged from the system. The concentration reduction rate can reach up to 95%. This equipment significantly reduces the waste liquid treatment costs for enterprises, with advantages such as a small footprint, mobility, high automation level, and requiring only electrical energy and a small amount of compressed air.

二、 处理流程:

不同类型废液需采取不同处理措施,如含油类原液需前端搭配油水分离机,后端搭配膜过滤以提高蒸馏水水质;含有机物或粘性液体需絮凝后蒸发以减少运维成本;含盐类低浓度液体可直接蒸发,高盐液体建议使用低温刮板结晶设备。

Treatment Process: Different types of waste liquids require different treatment measures. For example, oil-containing raw liquids require an oil-water separator at the front end and membrane filtration at the back end to improve the quality of distilled water. Organic or viscous liquids need flocculation before evaporation to reduce maintenance costs, while low-concentration liquids containing salts can be directly evaporated. For high-salt liquids, it is recommended to use low-temperature scraped crystallization equipment.

废液处理流程示意图

Waste Liquid Treatment Process Diagram

Waste Liquid Treatment Process Diagram

三、适用范围:

适用于各种行业废水处理,如电镀废液、阳极处理磷酸废液、乳化型切削液废水、研磨废液、涂料废液、氟酸处理废水等。

Application Range: Suitable for various industries' wastewater treatment needs, including electroplating waste liquid, anodizing phosphoric acid waste liquid, emulsified cutting fluid wastewater, grinding waste liquid, paint waste liquid, and hydrofluoric acid treatment wastewater.

四、 设备特点及型号:

设备具有多种型号,适应不同处理量需求,广泛应用于不同类型废水的处理。

Equipment Features and Models:

The equipment comes in various models to meet different processing capacity needs and is widely used in the treatment of different types of wastewater.

| 品名 | Item | 型号、规格 | Model, Specification | 台数 | Quantity | |

| 缸体主件 | 蒸馏罐 | Distillation Tank | 1台 | 1 unit | ||

| 冷凝器 | Condenser | φ900×2700 | φ900×2700 | 1台 | 1 unit | |

| 原液计量罐 | Raw Liquid Measuring Tank | 管壳式换热器SUS 2205 | Shell-and-Tube Heat Exchanger SUS 2205 | 1台 | 1 unit | |

| 蒸气过滤器 | Steam Filter | 316L | 316L | 1台 | 1 unit | |

| 螺旋桨式搅拌机 | Propeller Stirrer | SUS 316L | SUS 316L | 1台 | 1 unit | |

| 机械传动 | 减速机 | Reducer | 2205 | 2205 | 1台 | 1 unit |

| 真空泵 | Vacuum Pump | AC380V 3相 2.2Kw | AC380V 3 Phase 2.2kW | 1台 | 1 unit | |

| 回收水泵 | Recovery Water Pump | AC380V 3相 3.0kW | AC380V 3 Phase 3.0kW | 1台 | 1 unit | |

| 蒸气减压阀 | Steam Pressure Reducing Valve | AC380V 3相 0.4kW | AC380V 3 Phase 0.4kW | 1台 | 1 unit | |

| 1次蒸气疏水阀 | Primary Steam Trap Valve | 薄膜式减压阀 | Film Pressure Reducing Valve | 1台 | 1 unit | |

| 2次蒸气疏水阀 | Secondary Steam Trap Valve | 压力平衡式 | Pressure Balanced | 1台 | 1 unit | |

| 蒸气活塞阀 | Steam Piston Valve | 浮动式 | Floating | 1台 | 1 unit | |

| 前盖栓阀(主体) | Front Cover Plug Valve (Main Body) | 角座阀 | Angle Seat Valve | 2台 | 2 units | |

| 前盖栓阀(汽缸) | Front Cover Plug Valve (Cylinder) | SUS316L喷氟 汽缸式 | SUS316L Fluorine Spraying Cylinder Type | 1台 | 1 unit | |

| 自动球阀类 | Automatic Ball Valve | φ50×200 | φ50×200 | 1式 | 1 set | |

| 蒸气安全阀 | Steam Safety Valve | SCS14 空气驱动式 | SCS14 Air-Driven Type | 1台 | 1 unit | |

| 真空表 | Vacuum Gauge | 0~-100kPa | 0 to -100kPa | 1台 | 1 unit | |

| 计测空气 | Air Measurement | φ60*8A | φ60*8A | 1台 | 1 unit | |

| 过滤调节器 | Filter Regulator | 蒸气1次:0~1.0MPa | Steam 1st Stage: 0 to 1.0MPa | 1 unit | ||

| 压力表 | Pressure Gauge | 蒸气2次:0~0.3MPa | Steam 2nd Stage: 0 to 0.3MPa | 1台 | 1 unit | |

| Thermometer | 冷却水:0~0.5Mpa | Cooling Water: 0 to 0.5Mpa | 1台 | 1 unit | ||

| Measuring Tank Control LS | 0~100℃ 冷却水用 | 0 to 100℃ for Cooling Water Use | 2台 | 2 units | ||

| Buffer Tank Control LS | SUS 浮子式浮球开关 | SUS Float Type Float Switch | 1台 | 2 units | ||

| 温度计 | Measuring Tank Upper Limit LS | SUS 浮子式浮球开关 | SUS Float Type Float Switch | 2台 | 1 unit | |

| 计量罐控制LS | Buffer Tank Upper Limit LS | SUS 浮子式浮球开关 | SUS Float Type Float Switch | 1台 | 1 unit | |

| 缓冲液罐控制LS | Instrument Air Too Low PS | SUS 浮子式浮球开关 | SUS Float Type Float Switch | 1台 | 1 unit | |

| 计量罐上限LS | Cooling Water Too Low FS | PP | PP | 1台 | 1 unit | |

| 缓冲液罐上限LS | Steam Too High PS | PP | PP | 1台 | 1 unit | |

| 仪表空气过低PS | Steam Too Low PS | PVC | PVC | 1台 | 1 unit | |

| 冷却水过低FS | Raw Water Pipe Material | SUS304 | SUS304 | 1台 | 1 unit | |

| 蒸气过高PS | Recovery Water Pipe Material | SUS304 | SUS304 | 1台 | 1 unit | |

| 蒸气过低PS | Cooling Water Pipe Material | 尼龙管 ※使用卡扣式连接 | Nylon Pipe *Using Snap-fit Connection | 1台 | 1 unit | |

| 设备管路 | 原水管材 | Steam Pipe Material | PTFE 特氟纶 | PTFE Teflon | 1式 | 1 set |

| 回收水管材 | Steam Drainage Pipe Material | PTFE 特氟纶 | PTFE Teflon | 1式 | 1 set | |

| 冷却水管材 | Instrument Air Pipe Material | PTFE 特氟纶 | PTFE Teflon | 1式 | 1 set | |

| 蒸气管材 | Steam Pipe Material | PTFE 特氟纶 | PTFE Teflon | 1式 | 1 set | |

| 蒸气排水管材 | Steam Drainage Pipe Material | SiC×碳 氟橡胶 | SiC×Carbon Fluoro Rubber | 1式 | 1 set | |

| 仪表空气管材 | Instrument Air Pipe Material | NBR | NBR | 1式 | 1 set | |

| 蒸气管材 | Steam Pipe Material | CU板式换热器 | Copper Plate Heat Exchanger | 1式 | 1 set | |

| 原水管材 | Raw Water Pipe Material | SUS制 | Made of SUS | 1式 | 1 set | |

| 溶剂蒸气管材 | Solvent Steam Pipe Material | Q235防锈1回 | Q235 Anti-rust 1 coat | 1式 | 1 set | |

| 回收水管材 | Recovery Water Pipe Material | 面漆2回(N-3灰色) | Paint 2 coats (N-3 Gray) | 1式 | 1 set | |

| 机械式轴封 | Mechanical Shaft Seal | PLC&触摸屏 | PLC & Touch Screen | 2个 | 2 units | |

| 各部分橡胶垫片 | Rubber Gaskets for Various Parts | NBR | NBR | 1式 | 1 set | |

| 热交换器 | Heat Exchanger | CU板式换热器 | Copper Plate Heat Exchanger | 2台 | 2 units | |

| 回收水视镜 | Recovery Water Sight Glass | SUS制 | Made of SUS | 1个 | 1 unit | |

| 轴承部 | Bearing Parts | 2个 | 2 units | |||

| 机架 | 框架 | Frame | Q235防锈1回 | Q235 Anti-rust 1 coat | 1式 | 1 set |

| 面漆2回(N-3灰色) | Paint 2 coats (N-3 Gray) | |||||

| 电控及控制系统 | 控制系统 | Control System | PLC&触摸屏 | PLC & Touch Screen | 1套 | 1 set |

作者:沁聚

推荐内容 Recommended

- 2016年海绵城市建设技术指导专家委11-22

相关内容 Related

- 2016年海绵城市建设技术指导专家委11-22

- 沁聚荣获“国家高新技术企业”称11-22

- 农村人居环境整治提升五年行动方01-05

- 沁聚2021网络年会01-05

- 沁聚荣获“上海市青年突击队”称01-05

- 关于印发2016年全市黑臭河道整治工01-05